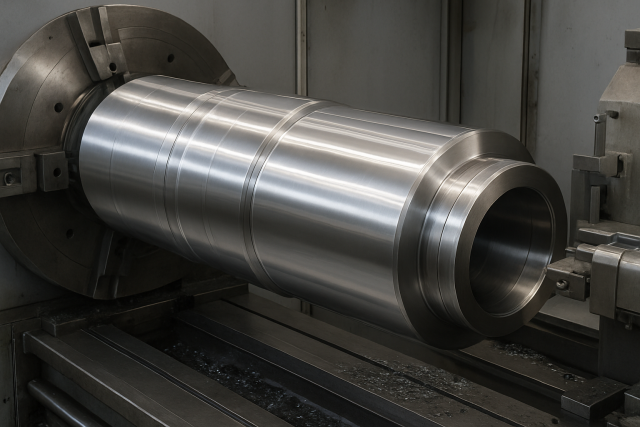

ZAAS machine shop is equipped with a wide array of specialized machine tools including vertical lathe machines, horizontal lathe machines, gear shaping/hobbing machines, heavy-duty radial drilling machines, universal milling machines, and surface grinding machines.

CNC machining technology is essential for precision and fast production. At ZAAS, we specialize in both manual and automated CNC machining, providing highly accurate, custom-manufactured components. Our state-of-the-art CNC section allows us to deliver precise results on non-standard spare parts and complex assemblies, making us a one-stop solution for all your manufacturing needs.

At ZAAS, we offer a comprehensive range of machining and engineering solutions designed to meet the highest standards of quality and precision. Backed by advanced technology and skilled craftsmanship, our services cover everything from custom part manufacturing to complex gear cutting and fabrication work — all delivered with reliability, accuracy, and efficiency.

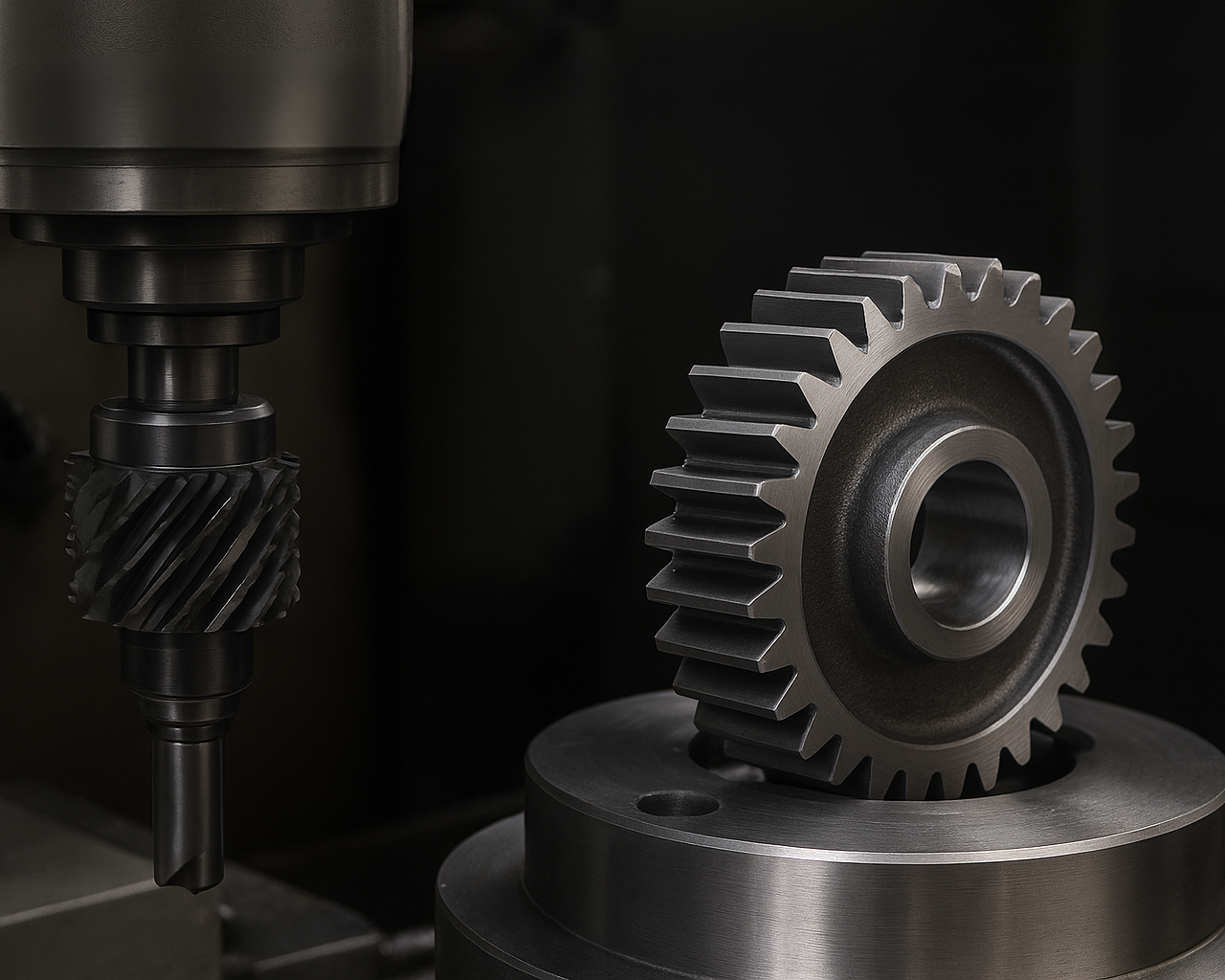

At ZAAS, we specialize in precision gear cutting for a wide range of industrial applications. Our expertise covers both the manufacturing of new gears and the refurbishment of existing units, ensuring high performance, durability, and custom solutions to meet every client’s requirements, while maintaining the highest standards of accuracy and efficiency.

Our Capabilities Include:

At ZAAS, we are committed to anticipating and exceeding the needs of our customers by consistently delivering high-quality products and services. Our management and staff focus on continual improvement in all aspects of our operations, particularly in customer satisfaction, turnaround time, and reliability. We ensure that our quality policy and objectives are clearly communicated and implemented throughout the organization. Monthly management meetings are conducted to review, refine, and reinforce our quality system and goals. We also foster an environment that encourages pride in workmanship, teamwork, and dedication among all employees.